ILVO

FWO

UGent

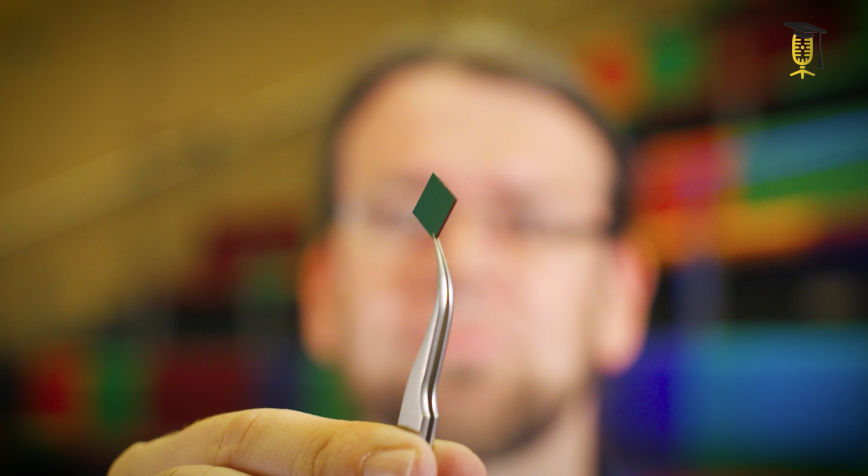

The green gold of the future

Why do scientists sometimes call microalgae "the green gold"? Well, in addition to biofuels and astronaut food, you could use them to make sunscreen. These tiny algae contain substances that protect them from sunlight, which can also come in handy for humans. Unfortunately, they don't naturally produce enough of those substances. Elke Vereecke researches how to grow microalgae packed with those sunlight-protecting components.